PVC Kugadzira

Chaizvoizvo, zvigadzirwa zvePVC zvinogadzirwa kubva muhupfu hwePVC nemaitiro ekupisa nekumanikidza.Iwo maviri maitiro makuru anoshandiswa mukugadzira ndeye extrusion yepombi uye jekiseni molding yekumisikidza.

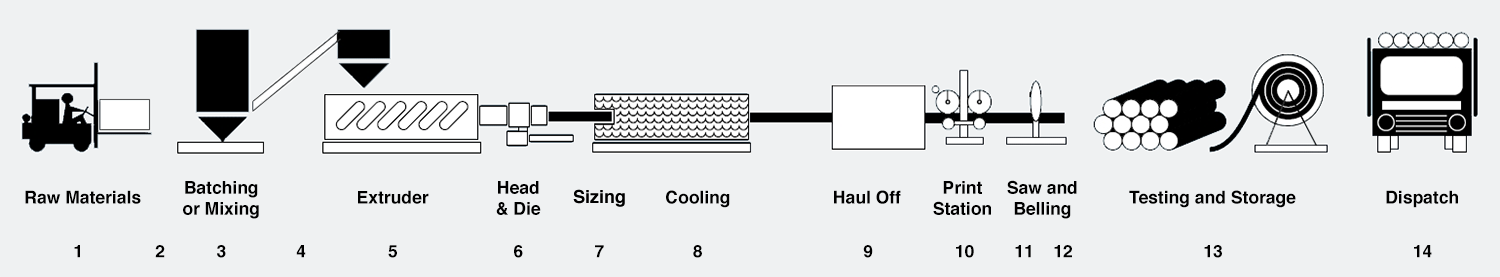

Kugadziriswa kwemazuva ano kwePVC kunosanganisira nzira dzakagadziridzwa dzesainzi dzinoda kutonga chaiko pamusoro pemaitiro akasiyana.Iyo polymer zvinhu ndeye yemahara inoyerera poda, iyo inoda kuwedzerwa kwema stabilizers uye kugadzirisa aids.Kugadzira uye kusanganisa matanho akakosha eiyo maitiro uye zvakaomesesa zvakatemwa zvinochengeterwa zvinopinda zvigadzirwa, batching uye kusanganisa.Kudyisa kune extrusion kana kuumba michina inogona kunge yakananga, nenzira ye "dry blend", kana kuti isati yagadziriswa mu "compound" granular.

Extrusion

Polymer uye zvinowedzerwa (1) zvinoyerwa nemazvo (2) uye zvinogadziriswa kuburikidza nekumhanyisa kumhanya kusanganisa (3) kusanganisa iyo mbishi musanganiswa wakagovaniswa wakaoma musanganiswa.Tembiricha yekusanganisa inosvika 120 ° C inowanikwa nekupisa kunopisa.Pamatanho akasiyana-siyana ekusanganisa maitiro, izvo zvinowedzera zvinonyunguduka uye zvishoma nezvishoma kupfeka iyo PVC polymer granules.Mushure mekusvika tembiricha inodiwa, musanganiswa wacho unoburitswa otomatiki mukamuri yekutonhodza iyo inokurumidza kudzikisa tembiricha kusvika ku50 ° C, nekudaro ichibvumira musanganiswa kuti uendeswe kune yepakati chengetedzo (4) uko kunyangwe tembiricha uye density kuenderana kunowanikwa.

Mwoyo wekuita, iyo extruder (5), ine tembiricha-inodzorwa, yakaganhurwa dhiramu umo inotenderedza chaiyo "screws".Mazuva ano extruder screws midziyo yakaoma, yakanyatsogadzirwa nendege dzakasiyana siyana kudzora kudzvanya uye kugera, yakagadzirwa mune izvo zvinhu, panguva dzese nhanho dzekuita.Iwo mapatya anopokana-anotenderedza screw kumisikidza inoshandiswa nevagadziri vese vakuru inopa yakagadziridzwa kugadzirisa.

Iyo PVC dryblend inomisikidzwa mudhiramu uye screws, iyo inozoshandura iyo yakaoma musanganiswa kuita inodiwa "kunyungudika" mamiriro, nekupisa, kudzvanywa uye kugera.Munguva yekufamba kwayo padivi pema screws, iyo PVC inopfuura nepakati akati wandei matunhu anomanikidza, homogenise uye vent rwizi rwekunyunguduka.Iyo yekupedzisira zone inowedzera kudzvanywa kwekuwedzera kunyungudika kuburikidza nemusoro uye kufa set (6) iyo inoumbwa zvinoenderana nehukuru hwepombi inodiwa uye kuyerera maitiro erukova rwekunyunguduka.Kana pombi yangosiya extrusion kufa, inokwidziridzwa nekupfuura nepakati peiyo chaiyo saizi sleeve ine vacuum yekunze.Izvi zvakakwana kuomesa kunze kwePVC uye kubata dhayamita yepombi panguva yekutonhodza kwekupedzisira mune inodzorwa mvura yekutonhodza dzimba (8).

Iyo pombi inodhonzwa kuburikidza nekuyera uye kutonhodza mashandiro neanodhonza kana kudhonza-kubvisa (9) nekukurumidza.Kudzora kumhanya kwakakosha zvikuru kana ichi chishandiswa nekuti kumhanya kunodhonzwa pombi kuchakanganisa kukora kwemadziro echigadzirwa chakapedzwa.Panyaya yerabha ring jointed pombi iyo yekukwevera inononoka panguva yakakodzera kuti iwedzere pombi munzvimbo yesoketi.

In-line printer (10) inomaka mapaipi nguva nenguva, iine chiziviso zvinoenderana nehukuru, kirasi, mhando, zuva, Nhamba yakajairwa, uye extruder nhamba.Saha inoitwa otomatiki (11) inocheka pombi kusvika pakureba kunodiwa.

Muchina wekubhera unoumba soketi pamagumo ehurefu hwega hwega hwepombi (12).Kune maviri akajairwa mafomu e socket.Papombi yerabha-ring jointed, chivharo chinoputika chinoshandiswa, nepo plain mandrel ichishandiswa kugadzira sockets joint sockets.Rubber ring pipe inoda chamfer pane spigot, iyo inourawa pachiteshi chesaha kana bhero unit.

Chigadzirwa chakapedzwa chinochengetwa munzvimbo dzekubatira kuti dziongororwe uye yekupedzisira marabhoritari kuyedzwa uye kugamuchirwa kwemhando (13).Kugadzirwa kwese kunoedzwa uye kunoongororwa zvinoenderana neyakakodzera Australian Standard uye/kana kune zvakatemwa zvemutengi.

Mushure mekuongorora uye kugamuchirwa, pombi inochengetwa kumirira kutumira kwekupedzisira (14).

Kune inotungamirwa PVC (PVC-O) mapaipi, iyo extrusion maitiro inoteverwa nekuwedzera nzira yekuwedzera iyo inoitika pasi yakanyatsotsanangurwa uye yakanyatso kudzora mamiriro ekushisa nekumanikidza.Iri panguva yekuwedzera iyo ma molecular orientation, iyo inopa simba repamusoro rakafanana nePVC-O, rinoitika.

Jekiseni Molding

PVC fittings inogadzirwa nehigh-pressure injection moulding.Mukupesana nekuenderera mberi extrusion, kuumba inodzokororwa cyclic process, apo "pfuti" yezvinyorwa inounzwa kune mold mune yega kutenderera.

PVC zvinhu, ingave yakaoma musanganiswa wehupfu kana fomu yegranular compound, igiravhiti inodyiswa kubva pane hopper iri pamusoro pejekiseni unit, kupinda mudhiramu rekugara screw inodzokororwa.

Iyo dhiramu inobhadhariswa huwandu hunodiwa hwepurasitiki ne screw inotenderera uye kuendesa zvinhu kumberi kwedhiramu.Nzvimbo ye screw yakaiswa kune yakatemerwa "shot size".Panguva iyi, kudzvinyirirwa uye kupisa "plasticise" zvinhu, izvo zvino mukunyunguduka kwayo, zvinomirira jekiseni muforoma.

Zvese izvi zvinoitika panguva yekutonhora kwepfuti yapfuura.Mushure menguva yakatarwa iyo mold ichavhura uye iyo yakapedzwa yakaumbwa yekumisikidza inoburitswa kubva mukuumbwa.

Iyo mold inobva yavhara uye purasitiki yakanyungudutswa kumberi kwembiru inoiswa jekiseni pasi pekudzvinyirirwa kukuru nescrew yava kuita seplunger.Plastiki inopinda muforoma kuti igadzire iyo inotevera yakakodzera.

Mushure mejekiseni, recharge inotanga apo iyo yakaumbwa inoenda kuburikidza nekutonhora kwayo.

Nguva yekutumira: Jun-23-2022