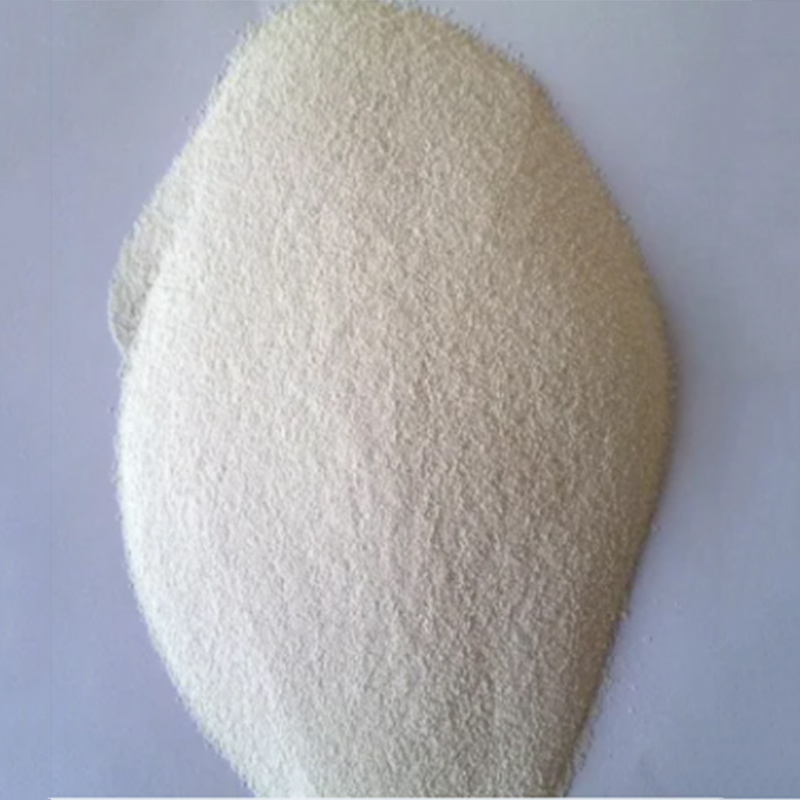

Raw zvinhu zvekugadzira mapaipi ePVC

Raw zvinhu zvekugadzira PVC mapaipi,

PVC resin, PVC kugadzira pombi,

S-1000 polyvinyl chloride resin inogadzirwa nekumiswa kwepolymerization maitiro uchishandisa vinyl chloride monomer seyakagadzirwa.Iyo imhando yepolymer komputa ine hukama hwehukama hwe1.35 ~ 1.40.Nzvimbo yayo yekunyungudika inenge 70 ~ 85 ℃.Kusagadzikana kwemafuta uye kushomeka kwechiedza, pamusoro pe100 ℃ kana nguva refu pasi pezuva hydrogen chloride inotanga kuora, kugadzirwa kwepurasitiki kunoda kuwedzera stabilizers.Chigadzirwa chacho chinofanira kuchengetwa muimba yakaoma uye inofefetera.Zvinoenderana nehuwandu hweplasticizer, kupfava kwepurasitiki kunogona kugadziriswa, uye paste resin inogona kuwanikwa neemulsion polymerization.

Giredhi S-1000 inogona kushandiswa kugadzira yakapfava firimu, shiti, manmade dehwe, pombi, yakaumbwa bar, bellow, cable kudzivirira pombi, kurongedza firimu, chete uye zvimwe zvakapfava sundry zvinhu.

Parameters

| Giredhi | PVC S-1000 | Mashoko | ||

| Item | Guarantee kukosha | Test method | ||

| Avhareji yedhigirii repolymerization | 970-1070 | GB/T 5761, Appendix A | K kukosha 65-67 | |

| Kuwanda kwekuwanda, g/ml | 0.48-0.58 | Q/SH3055.77-2006, Appendikisi B | ||

| Volatiles yemukati (mvura inosanganisirwa), %, ≤ | 0.30 | Q/SH3055.77-2006, Appendikisi C | ||

| Plasticiser absorption ye100g resin, g, ≥ | 20 | Q/SH3055.77-2006, Appendikisi D | ||

| VCM zvakasara, mg/kg ≤ | 5 | GB/T 4615-1987 | ||

| Kuongororwa % | 2.0 | 2.0 | Nzira 1: GB/T 5761, Appendikisi B Nzira yechipiri: Q/SH3055.77-2006, Appendikisi A | |

| 95 | 95 | |||

| Nhamba yehove, Nha./400cm2, ≤ | 20 | Q/SH3055.77-2006, Appendix E | ||

| Nhamba yezvimedu zvetsvina, Kwete., ≤ | 16 | GB/T 9348-1988 | ||

| Kuchena (160ºC, 10minutes gare gare), %, ≥ | 78 | GB/T 15595-95 | ||

Mapaipi ePVC anogadzirwa neextrusion yeraw material PVC, uye anowanzo kutevedzera nhanho dzakafanana dzeakajairika pombi extrusion mashandiro:

1.Kudyiswa kwehupfu yakasvibiswa inonzi resin uye filler muPVC twin screw extruder;

2. Kunyunguduka uye kupisa munzvimbo dzakawanda dzeextruder;

3. Kubuditsa nedhii kuti iumbe kuita pombi;

4.Kutonhora kwepombi yakagadzirwa (nekupfira mvura papombi);uye

5. Kucheka kwePVC mapaipi kusvika paurefu hunodiwa.

Iyo mbishi yekugadzira mapaipi ePVC iresin uye filler (kunyanya calcium carbonate, kana inowanzozivikanwa sematombo).Musanganiswa wakajairika i1 kilogiramu (kg) yeresin ine 1 kilogram yekuzadza.Maitiro ekugadzira anowanzo otomatiki, nevashandi vanodyisa zvigadzirwa pakutanga kwemaitiro, vachitarisa tembiricha mukuita uye kutarisa chigadzirwa chekupedzisira kune chero hurema huri pachena vasati varongedza uye kutumira kune vatengi.Vashandi vose vakadzidziswa uye vanokwanisa kuita mabasa ose aya nemazvo.Chinhu chikuru chekugadzira mapaipi ePVC ihupfu inonzi PVC resin.